GX4500 Steel Cord Conveyor Belt

Basic Information

| Place of Origin: | Qingdao, China |

| Brand Name: | TSKY |

| Certification: | SGS, ISO, BV, CE |

| Model Number: | GX4500 |

| Minimum Order Quantity: | 100m |

| Price: | Negotiation |

| Packaging Details: | Export standard container: 20GP or 40GP, 40HC |

| Delivery Time: | 7-15 working days after confirmed order |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10000m per day |

Detail Information

| Name: | GX Series GX4500 Steel Cord Conveyor Belt | Longitudinal Tensile Strength: | 4500N/mm |

| Thickness: | 30mm | Max. Diameter Of Wire Rope: | 9.7mm |

| Wire Rope Spacing: | 16mm | Reference Mass: | 49.8kg/m² |

| Minimum Pulley Diameter: | 1800mm | Belt Width: | 1000mm-2200mm |

| No. Of Wire Ropes: | 60-133 | Warranty: | 12 Months |

| High Light: | GX4500 Steel Cord Conveyor Belt,

9.7mm Steel Cord Conveyor Belt, GX4500 steel cord belt |

||

Product Description

GX Series GX4500 Steel Cord Conveyor Belt

Features of GX Series GX4500 Steel Cord Conveyor Belt

The GX Series GX4500 steel cord conveyor belt is widely used in coal, mine, port, metallurgy, power supply, chemical engineering and other fields for conveying materials.

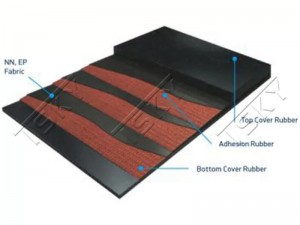

The GX Series GX4500 steel cord conveyor belt core is comprised of longitudinally and evenly arranged non-spinning galvanized steel cord and high adhesive core rubber, covered with the top rubber and bottom cover.

The GX Series GX4500 steel cord conveyor belt has these advantages: high tensile strength, long service life, short elongation under service, good groove formation property and good anti-flexure property, which make it suitable for conveying materials across long distance with large capacity and high speed.

The GX Series GX4500 steel cord conveyor belt has three different types: standard structure type, new structure type and horizontally strengthened type.

The new structure type has these features:

The rubber core has enough penetration capacity to penetrate the spaces between the steel strands. Its high adhesive strength between the rubber and steel and goo anti-corrosive property can effectively alleviate the shear force and strand twisting. Its superior dynamic fatigue durability imparts the product longer service life.

The horizontally strengthened type has these features:

The strengthening layers such as steel cords, steel ropes, fiber rope and fabrics are transversally laid on one side or two sides of the wire ropes. It has good impact strength and high tearing strength.

Technical Parameter of ST Series Steel Cord Conveyor Belt

|

Model |

ST500 |

ST630 |

ST800 |

ST1000 |

ST1250 |

ST1400 |

ST1600 |

ST1800 |

ST2000 |

ST2250 |

ST2500 |

ST2800 |

ST3150 |

ST3500 |

ST4000 |

ST4500 |

ST5000 |

ST5400 |

ST6300 |

ST7000 |

ST7500 |

|

|

Min. Tensile Strength (N/mm)

|

500 |

630 |

800 |

1000 |

1250 |

1400 |

1600 |

1800 |

2000 |

2250 |

2500 |

2800 |

3150 |

3500 |

4000 |

4500 |

5000 |

5400 |

6300 |

7000 |

7500 |

|

|

Max. Diameter of Wire Rope (mm) |

3.0 |

3.0 |

3.5 |

4.0 |

4.5 |

5.0 |

5.0 |

5.6 |

6.0 |

6.6 |

7.2 |

7.2 |

8.1 |

8.6 |

8.9 |

9.7 |

10.9 |

11.3 |

12.8 |

13.5 |

15.0 |

|

|

Wire Rope Spacing (mm) |

14.0 |

10.0 |

10.0 |

12.0 |

12.0 |

14.0 |

12.0 |

13.5 |

12.0 |

11.0 |

15.0 |

13.5 |

15.0 |

15.0 |

15.0 |

16.0 |

17.0 |

17.0 |

19.5 |

19.5 |

21.0 |

|

|

Minimum Thickness of Rubber Cover |

4.0 |

4.0 |

4.0 |

4.0 |

4.0 |

4.0 |

4.0 |

4.0 |

4.0 |

4.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Belt Width |

Limit Deviation |

No. of Wire Ropes |

||||||||||||||||||||

|

500 |

±10/-5 |

33 |

45 |

45 |

39 |

39 |

34 |

39 |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

|

650 |

±10/-7 |

44 |

60 |

60 |

51 |

51 |

45 |

51 |

46 |

52 |

56 |

41 |

46 |

41 |

41 |

41 |

39 |

36 |

N/A |

N/A |

N/A |

N/A |

|

800 |

±10/-8 |

54 |

75 |

75 |

63 |

63 |

55 |

63 |

57 |

63 |

69 |

50 |

57 |

50 |

50 |

51 |

48 |

45 |

45 |

N/A |

N/A |

N/A |

|

1000 |

±10 |

68 |

95 |

95 |

79 |

79 |

68 |

79 |

71 |

79 |

86 |

64 |

71 |

64 |

64 |

64 |

59 |

55 |

55 |

N/A |

N/A |

N/A |

|

1200 |

±10 |

83 |

113 |

113 |

94 |

94 |

82 |

94 |

85 |

94 |

104 |

76 |

85 |

76 |

77 |

77 |

71 |

66 |

66 |

58 |

59 |

54 |

|

1400 |

±12 |

96 |

133 |

133 |

111 |

111 |

97 |

111 |

100 |

111 |

122 |

89 |

99 |

89 |

90 |

90 |

84 |

78 |

78 |

68 |

69 |

64 |

|

1600 |

±12 |

111 |

151 |

151 |

126 |

126 |

111 |

126 |

114 |

126 |

140 |

101 |

114 |

101 |

104 |

104 |

96 |

90 |

90 |

78 |

80 |

73 |

|

1800 |

±14 |

125 |

171 |

171 |

143 |

143 |

125 |

143 |

129 |

143 |

159 |

114 |

128 |

114 |

117 |

117 |

109 |

102 |

102 |

89 |

90 |

83 |

|

2000 |

±14 |

139 |

191 |

191 |

159 |

159 |

139 |

159 |

144 |

159 |

177 |

128 |

143 |

128 |

130 |

130 |

121 |

113 |

113 |

99 |

100 |

92 |

|

2200 |

±15 |

153 |

211 |

211 |

176 |

176 |

154 |

176 |

159 |

176 |

195 |

141 |

158 |

141 |

144 |

144 |

134 |

125 |

125 |

109 |

110 |

102 |

|

2400 |

±15 |

167 |

231 |

231 |

193 |

193 |

168 |

193 |

174 |

193 |

213 |

155 |

173 |

155 |

157 |

157 |

146 |

137 |

137 |

119 |

119 |

110 |

|

2600 |

±15 |

181 |

251 |

251 |

209 |

209 |

182 |

209 |

189 |

209 |

231 |

168 |

188 |

168 |

170 |

170 |

159 |

149 |

149 |

129 |

129 |

120 |

|

2800 |

±15 |

196 |

271 |

271 |

226 |

226 |

197 |

226 |

203 |

326 |

249 |

181 |

202 |

181 |

183 |

183 |

171 |

161 |

161 |

139 |

139 |

129 |

|

3000 |

±15 |

210 |

291 |

291 |

243 |

243 |

211 |

243 |

218 |

243 |

268 |

195 |

217 |

195 |

195 |

195 |

183 |

172 |

172 |

149 |

149 |

139 |

|

3200 |

±15 |

224 |

311 |

311 |

260 |

260 |

225 |

260 |

233 |

260 |

286 |

208 |

232 |

208 |

208 |

208 |

196 |

184 |

184 |

160 |

160 |

149 |

| Note:

The length of single roll of conveyor belt is 100m-350m, depending on its thickness, width, transportation and installation conditions. The length shall be determined through discussion of supplier and buyer. The quality of rubber conveyor belt varies with thickness and density of rubber cover layer. |

||||||||||||||||||||||

Technical Parameter of GX Series GX4500 Steel Cord Conveyor Belt

|

Model |

GX630 |

GX800 |

GX1000 |

GX1250 |

GX1600 |

GX2000 |

GX2500 |

GX3000 |

GX3500 |

GX4000 |

GX4500 |

GX5000 |

GX5500 |

|

Thickness |

6+7+6 |

6+7+6 |

6+7+6 |

6+7+6 |

7+9+7 |

7+9+7 |

8+11+8 |

8+12+8 |

8+12+8 |

8+13+8 |

8+14+8 |

8+14+8 |

8+16+8 |

|

Longitudinal Tensile Strength (N/mm) |

630 |

800 |

1000 |

1250 |

1600 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

5000 |

5500 |

|

Max. Diameter of Wire Rope (mm) |

4.5 |

4.5 |

4.5 |

4.5 |

6.0 |

6.0 |

7.2 |

8.3 |

8.7 |

9.1 |

9.7 |

10.9 |

11.3 |

|

Wire Rope Spacing (mm) |

20 |

17 |

13.5 |

11 |

20 |

16 |

17 |

18 |

18 |

17 |

16 |

17 |

17 |

|

Thickness (mm) |

19 |

19 |

19 |

19 |

23 |

23 |

27 |

28 |

28 |

29 |

30 |

30 |

32 |

|

Reference Mass (kg/m²) |

23.9 |

21.3 |

25 |

25.7 |

32.2 |

33.7 |

40.2 |

41.9 |

43.6 |

46.6 |

49.8 |

51.8 |

55.9 |

|

Minimum Pulley Diameter (mm) |

800 |

800 |

800 |

800 |

1000 |

1000 |

1250 |

1400 |

1600 |

1600 |

1800 |

1800 |

2000 |

|

Width (mm) |

No. of Wire Ropes |

||||||||||||

|

800 |

38 |

45 |

56 |

69 |

38 |

47 |

44 |

43 |

N/A |

N/A |

N/A |

N/A |

N/A |

|

1000 |

48 |

56 |

70 |

87 |

48 |

60 |

56 |

53 |

53 |

56 |

60 |

56 |

56 |

|

1200 |

N/A |

68 |

86 |

104 |

58 |

72 |

68 |

67 |

67 |

68 |

72 |

68 |

68 |

|

1400 |

N/A |

N/A |

100 |

122 |

66 |

84 |

78 |

74 |

74 |

79 |

84 |

79 |

79 |

|

1600 |

N/A |

N/A |

116 |

140 |

76 |

95 |

90 |

86 |

86 |

90 |

96 |

91 |

91 |

|

1800 |

N/A |

N/A |

127 |

157 |

86 |

108 |

102 |

96 |

96 |

101 |

107 |

101 |

103 |

|

2000 |

N/A |

N/A |

142 |

173 |

96 |

120 |

113 |

107 |

107 |

113 |

120 |

114 |

114 |

|

2200 |

N/A |

N/A |

N/A |

N/A |

N/A |

132 |

125 |

118 |

118 |

125 |

133 |

125 |

125 |