HLS180 Tower Batching Plant

Basic Information

| Place of Origin: | Qingdao China |

| Brand Name: | TSKY |

| Certification: | ISO, CE, BV, FDA, SGS |

| Model Number: | HLS180 |

| Minimum Order Quantity: | 1 sets |

| Price: | Negotiable |

| Packaging Details: | 20GP, 40GP or 40HC container |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50 sets/month |

Detail Information

| Name: | HLS180 ECO-Friendly High Capacity Tower Concrete Batching Plant | Theoretical Productivity: | 180m3/h |

| Mixer Type: | TSKY MS3000 | Motor Power:: | 2*75Kw |

| Discharging Height: | 4.0m | Storage Hopper Capacity: | 4*25m3 |

| Flat Belt: | B=800mm | Aggregate Batcher: | PLD4800 |

| Aggregates Max. Diameter: | Φ80mm | Aggregates Weighting Precision: | ±2% |

| Powder/Water/Additive Weighing Precision: | ±1% | Bolted Cement Silo: | 4*100T |

| Power Voltage/Frequency: | AC380V / 50HZ | Warranty: | 12 Months |

| High Light: | HLS180 tower batching plant,

50HZ Tower Batching Plant, HLS180 concrete mixing plant |

||

Product Description

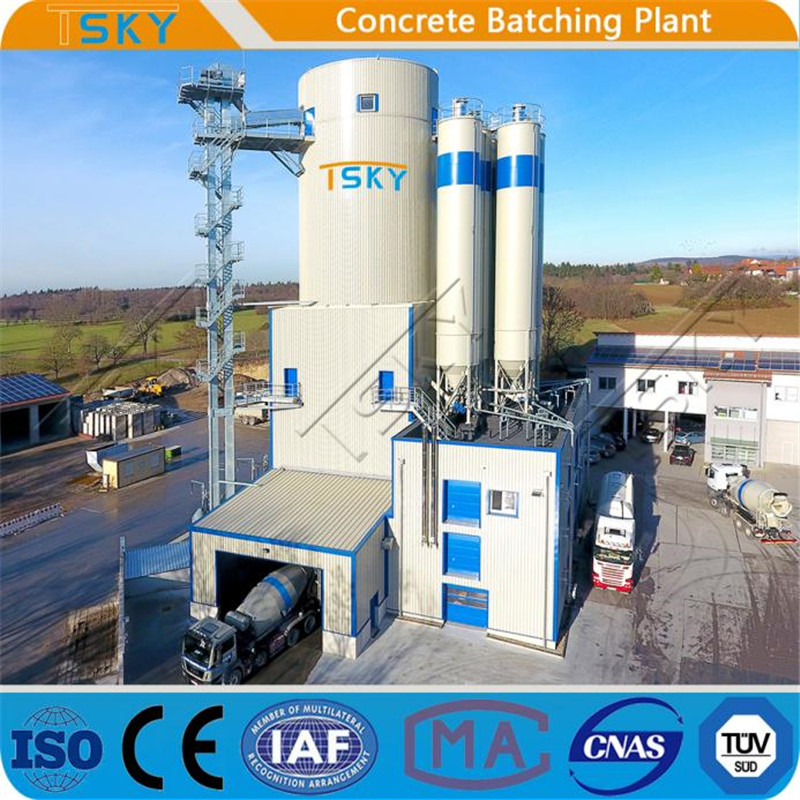

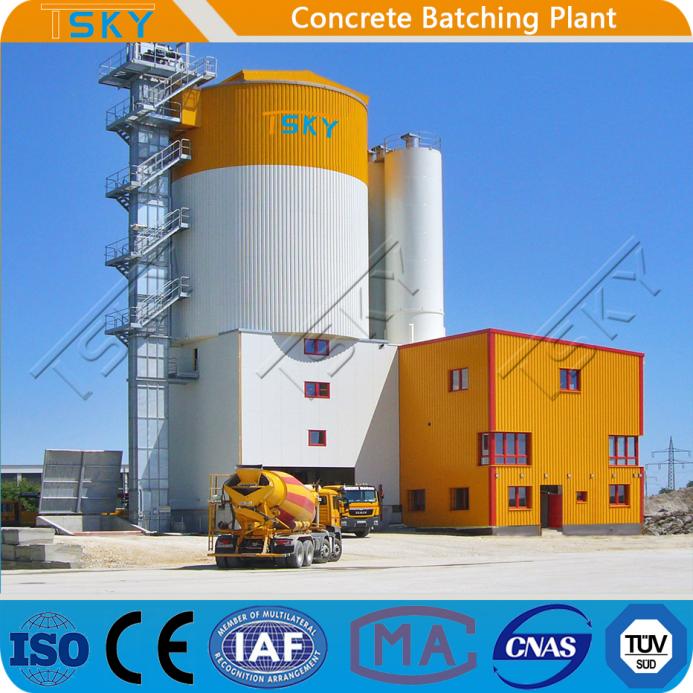

HLS180 ECO-Friendly High Capacity Tower Concrete Batching Plant

Features Of HLS180 ECO-Friendly High Capacity Tower Concrete Batching Plant

1. HLS180 concrete batch plant which is used for concrete machine, Productivity about 180m3/h;

2. The control system for this equipment includes both program and manual modes.

3. The concrete batch plant, also known as horizontal mixing equipment, is utilized for mixing concrete.

4. The advantages of this equipment include its small size, high efficiency, and ease of automatic control.

5. This equipment is also characterized by its low cost and low energy consumption.

The Description Of HLS180 ECO-Friendly High Capacity Tower Concrete Batching Plant

The HZS180 concrete batching plant is a kind of concrete machinery that employs an LSY type screw conveyor. Its transmission system is categorized into two types: the aggregate conveyor and the powder conveyor.

1. Modular structure and convenient to remove

2. By utilizing a twin shaft compulsory concrete mixer, the MS3000 concrete mixer enhances the quality and efficiency of mixing for both concrete and aggregates.

3. The PLD4800 concrete batching machine enables precise measurement and high production efficiency for aggregate batching.

4. The electronic scale used for measuring powder materials ensures a high level of accuracy in proportioning.

5. Use electronic scales to measure water volume with higher accuracy.

6. Control system: This machine is equipped with a computer control system, which can realize automatic and manual control. Simple operation and easy management.

7. This machine is suitable for small construction sites, prefabricated parts factories, and commercial concrete production plants. It is especially suitable for providing flow of high strength concrete for railway, road and other applications.

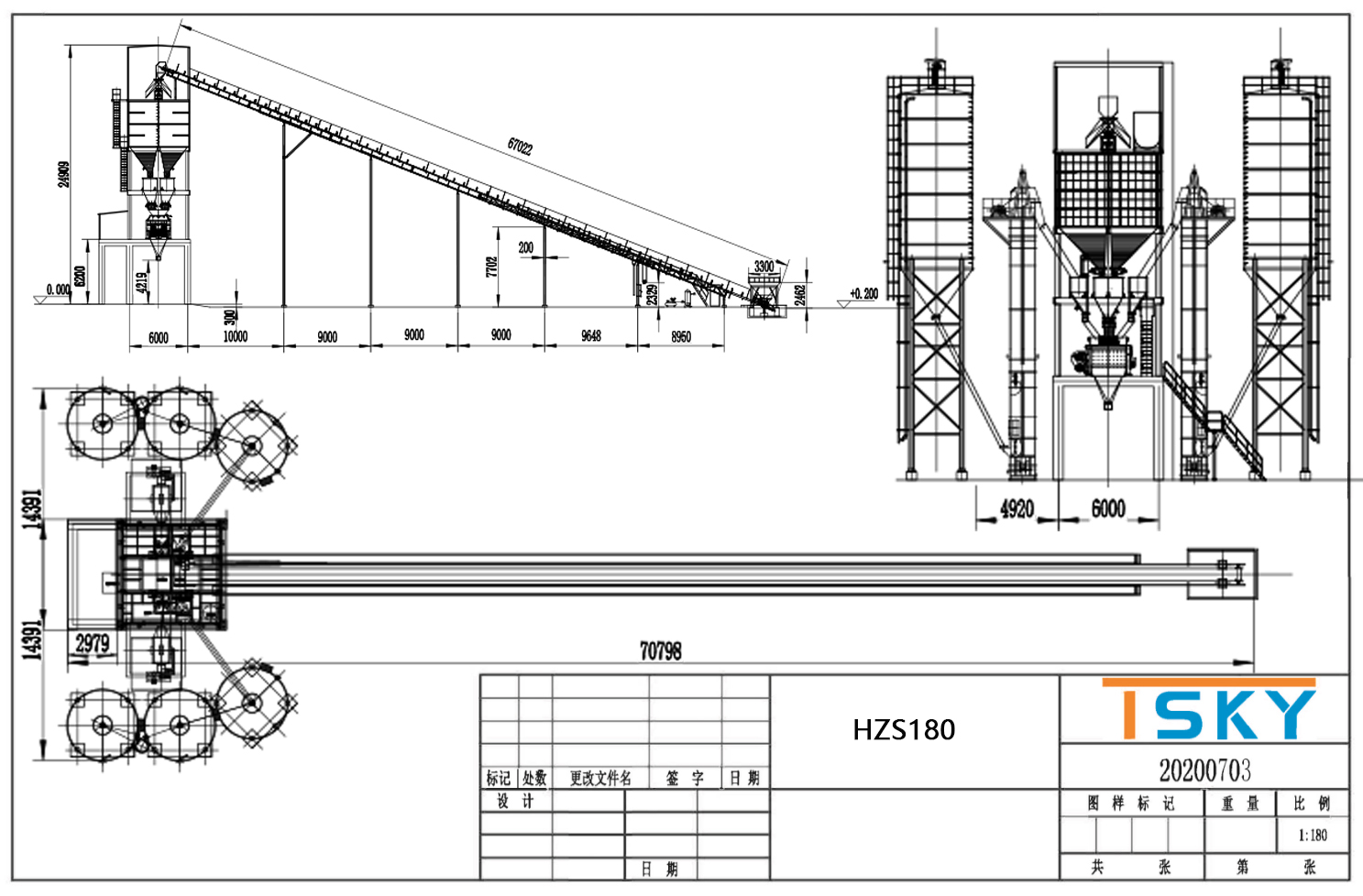

The Layout Drawings Of HLS180 ECO-Friendly High Capacity Tower Concrete Batching Plant

Technical Data of HLS180 Fully Automatic Operation Compact Tower Concrete mixing Plant

|

Model |

HZS25 |

HZS35 |

HZS50 |

HZS60 |

HZS75 |

HZS90 |

HZS120 |

HZS180 |

HZS240 |

|

|

Theoretical Productivity (m3/h) |

25 |

35 |

50 |

60 |

75 |

90 |

120 |

180 |

240 |

|

|

Mixer Model |

MS500 |

MS750 |

MS1000 |

MS1000 |

MS1500 |

MS1500 |

MS2000 |

MS3000 |

MS4000 |

|

|

Motor power(kw) |

18.5 |

30 |

18.5*2 |

18.5*2 |

30*2 |

30*2 |

37*2 |

55*2 |

75*2 |

|

|

Aggregate batcher |

PLD800 |

PLD1200 |

PLD1600 |

PLD2400 |

PLD2400 |

PLD2400 |

PLD3200 |

PLD4800 |

PLD4800 |

|

|

Aggregate Bins Capacity(m3) |

2*6 |

3*6 |

3*12 |

3*12 |

3*12 |

3*12 |

4*20 |

4*20 |

4*25 |

|

|

Max. Aggregate Diameter(mm) |

Φ80 |

Φ80 |

Φ80 |

Φ80 |

Φ80 |

Φ80 |

Φ80 |

Φ80 |

Φ80 |

|

|

Aggregate Feeding type |

Skip hopper |

Skip hopper |

Skip hopper |

Skip hopper /Belt type |

Skip hopper /Belt type |

Belt type |

Belt type |

Belt type |

Belt Type |

|

|

Cement Silo(T) |

60/100 |

60/100 |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

|

Discharge height (m) |

3.8 |

3.8 |

3.8 |

4.0 |

4.0 |

4.0 |

4.0 |

4.2 |

4.2 |

|

|

Cycle time (s) |

60 |

60 |

60 |

60 |

60 |

60 |

60 |

60 |

60 |

|

|

Weighing accuracy |

Aggregate |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

|

Cement |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

|

|

Water |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

±0.01 |

|

|

Additive |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

±0.02 |

|

|

Total Power (kw) |

45 |

60 |

75 |

80 |

110 |

150 |

175 |

215 |

295 |

|

|

Total Weight (T) |

10 |

13 |

18 |

32 |

24 |

37 |

60 |

72 |

100 |

|

|

Dimension L*W*H (m) |

Skip hopper Feed |

13*9.4*19.2 |

15.2*9.4*19.2 |

15.4*12.3*19.2 |

23*15*19.4 |

25.7*15*19.4 |

27.8*15*19.4 |

34*13.2*19.4 |

40*19*18.5 |

/ |

|

Belt Feed |

/ |

/ |

/ |

31.4*15.4*19.4 |

26.6*17.3*19.4 |

26.6*17.3*19.4 |

46.7*23*20 |

43.5*21*20 |

48*23*20 |

|

The Main Parts’ Characteristics

The batching plant features a computer-optimized design, advanced system configuration, and high modularity. Its layout is well-planned and offers convenient installation and debugging, catering to various users' needs in the concrete production industry. Overhead aggregate storage and measuring systems enhance equipment productivity. The control system employs internationally recognized components, ensuring reliable operation, stable performance, and accurate measurement. Furthermore, its industrial design and ergonomic processing result in a unique structure, beautiful appearance, excellent environmental protection performance, simple operation, and convenient maintenance.

Main Parts of HLS180 Fully Automatic Operation Compact Tower Concrete mixing Plant

|

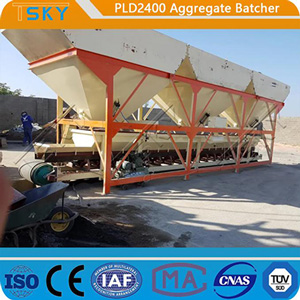

Aggregate Batching System PLD4800 Customization 3/4 hoppers with belt conveyor, pneumatic discharging mode with independent/cumulative weighting. |

|

|

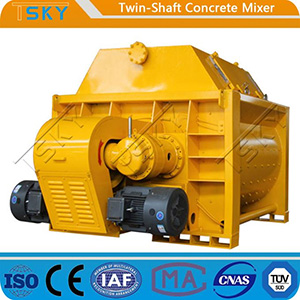

Twin-Shaft Mixer MS3000 Equipped with twin-horizontal shaft concrete mixer; Discharging height is 4.0m. Pneumatic/Hydraulic control, easy replacing of wearing parts, such as liner plates. |

|

|

Belt Type Aggregate Feeding |

Automatic control system Full-automatic PLC/Centralized control with the emergency stop button and safety control key. TV monitoring systems for batching machine, concrete mixer, and discharging mouth are optional for clients. |

|

|

Bolted Cement Silo modular making with dust collector, broken arch, pressure relief valve, level gauge |

|

||

|

|

Butterfly Valve |

||

|

Screw conveyor to feed powders |

|

||

|

|

Weighing system |

|

|