Environment Friendly Tower Type HL90 Concrete Batching Plant

Basic Information

| Place of Origin: | Qingdao, China |

| Brand Name: | TSKY |

| Certification: | SGS, ISO, BV, CE |

| Model Number: | HL90 |

| Minimum Order Quantity: | 1 set |

| Price: | Negotiation |

| Packaging Details: | Export standard container: 20GP or 40GP, 40HC |

| Delivery Time: | 7-15 working days after confirmed order |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10 sets per month |

Detail Information

| Name: | HL90 Environment Friendly Tower Type Concrete Batching Plant | Theoretical Productivity: | 90m3/h |

| Mixer Type: | TSKY MS/MP1500 | Mixing Motor Power: | 55Kw |

| Discharging Height: | 3.8m/4.2m | Storage Hopper Capacity: | 4*20m³ |

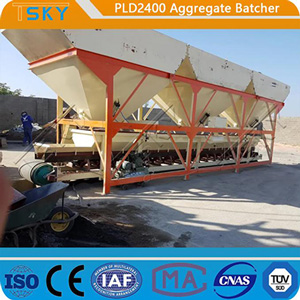

| Aggregate Batcher: | PLD2400 | Aggregates Max. Diameter: | Φ80mm |

| Aggregates Weighting Precision: | ±2% | Powder/Water/Additive: | ±1% |

| Bolted Cement Silo: | As Per Customer's Demand | Power Voltage/Frequency: | AC380V / 50HZ |

| Warranty: | 12 Months | ||

| High Light: | HL90 Concrete Batching Plant,

90m³h Concrete Batching Plant, HL90 concrete batching systems |

||

Product Description

HL90 Environment Friendly Tower Type Concrete Batching Plant

Tower type concrete batching plant , in addition to having the integrated features of the horizontal type plants, has the added benefit of larger storage capacities and the benefit of gravity batching.

Features Of HL90 Environment Friendly Tower Type Concrete Batching Plant

Wide Range Of Application

The HL90 environment friendly tower type concrete batching plant consists of conveying system, storage system, weighing system, concrete mixing system and control system. It is widely used in large and medium-sized construction sites, commercial concrete, prefabricated components and other concrete centralized mixing places.

Excellent Mixing Performance

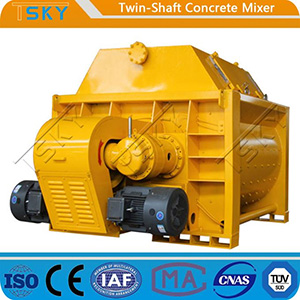

The equipped MS twin-shaft mixer or MP planetary mixer has excellent performance, good mixing quality and high production efficiency. The accurate arrangement of mixing arms allows the rapid mixing of all types of quality concrete (dry, semi-dry and so on).

Advanced Control System

The HL90 environment friendly tower type concrete batching plant adopts the computer network and automatic control, which can achieve the network monitoring and automatic controlling to manage and control the whole process of concrete production.

Environment Friendly

All the raw materials, from the feeding, batching, weighing, throwing into the mixer and discharging, are all in sealed structure. The completely packed mixing main building and aggregate belt conveying system significantly reduce the dust pollution and noise. Negative pressure pulse dust collecting system can thoroughly solve the dust pollution problem during the production.

Easy Maintenance

Humanized large maintenance platform and stairs are easy and convenient for repair and maintenance.

Technical Parameter of HL90 Environment Friendly Tower Type Concrete Batching Plant

|

Model |

HL60 |

HL90 |

HL120 |

HL180 |

HL240 |

|

Theoretical Productivity |

60m³/h |

90m³/h |

120m³/h |

180m³/h |

240m³/h |

|

Mixer Model |

MS/MP1000 |

MS/MP1500 |

MS/MP2000 |

MS/MP3000 |

MS/MP4000 |

|

Mixing Motor Power |

37Kw |

55Kw |

75Kw |

110Kw |

150Kw |

|

Feeding Mode |

Belt Conveyor Or Skip Hoist Conveyor |

||||

|

Cycling Period |

60s |

60s |

60s |

60s |

60s |

|

Max. Grain Size |

80/40mm |

80/40mm |

80/50mm |

80/50mm |

80mm |

|

Aggregate Bin Capacity |

4*20m³ |

4*20m³ |

4*25m³ |

4*25m³ |

4*40m³ |

|

Aggregate Weighing Precision |

±2% |

±2% |

±2% |

±2% |

±2% |

|

Cement Weighing Precision |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Fly Ash Weighing Precision |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Water Weighing Precision |

±1% |

±1% |

±1% |

±1% |

±1% |

|

Additive Weighing Precision |

±1% |

±1% |

±1% |

±1% |

±1% |

The Main Parts’ Characteristics

The mixing building adopts computer optimization design, advanced system configuration, high degree of modularizatoin, reasonable layout, convenient installation and debugging, which can meet the needs of different users to the concrete building. Overhead type of aggregate storage measurement system greatly improves the productivity of the equipment. The main components of the control system adopt international famous brand of imported components. It assures the reliable work, stable performance and accurate measurement. Perfect industrial design and thorough ergonomics processing make it unique structure, beautiful appearance, excellent environmental performance comfortable operation and convenient maintenance.

Main Parts of HLS180 Fully Automatic Operation Compact Tower Concrete mixing Plant

|

Aggregate Batching System PLD4800 Customization 3/4 hoppers with belt conveyor, pneumatic discharging mode with independent/cumulative weighting. |

|

|

Twin-Shaft Mixer MS3000 Equipped with twin-horizontal shaft concrete mixer; Discharging height is 4.0m. Pneumatic/Hydraulic control, easy replacing of wearing parts, such as liner plates. |

|

|

Belt Type Aggregate Feeding |

Automatic control system Full-automatic PLC/Centralized control with the emergency stop button and safety control key. TV monitoring systems for batching machine, concrete mixer, and discharging mouth are optional for clients. |

|

|

Bolted Cement Silo modular making with dust collector, broken arch, pressure relief valve, level gauge |

|

||

|

|

Butterfly Valve |

||

|

Screw conveyor to feed powders |

|

||

|

|

Weighing system |

|

|