Small Size HZS120 Mobile Concrete Batching Plant

Basic Information

| Place of Origin: | Qingdao China |

| Brand Name: | TSKY |

| Certification: | ISO, CE, BV, FDA, SGS |

| Model Number: | HZS120 |

| Minimum Order Quantity: | 1 sets |

| Price: | Negotiable |

| Packaging Details: | 20GP, 40GP or 40HC container |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 50 sets/month |

Detail Information

| Name: | HZS120 Container Moudlar High Mobility Concrete Batching Plant | Theoretical Productivity: | 120m3/h |

| Mixer Type: | TSKY MS2000 | Motor Power:: | 2*37Kw |

| Discharging Height: | 4.0m | Storage Hopper Capacity: | 4*20m3 |

| Flat Belt: | B=800mm | Aggregate Batcher: | PLD3200 |

| Aggregates Max. Diameter: | Φ120mm | Aggregates Weighting Precision: | ±2% |

| Powder/Water/Additive Weighing Precision: | ±1% | Bolted Cement Silo: | 4*100T |

| Power Voltage/Frequency: | AC380V / 50HZ | Warranty: | 12 Months |

| High Light: | HZS120 Mobile Concrete Batching Plant,120m3 Mobile Concrete Batching Plant,

HZS120 mobile concrete plant |

||

Product Description

HZS120 Container Moudlar High Mobility Concrete Batching Plant

Features Of HZS120 Container Moudlar High Mobility Concrete Batching Plant

1. HZS120 concrete batch plant which is used for concrete machine, Productivity about 120m3/h;

2. The control method including Program and manual control system;

3. Horizontal mixing equipment also called concrete batch plant;

4. Its advantages: Small size, easy to control automatically, high efficiency;

5. Low cost and low energy consumption.

The Description of HZS120 Container Moudlar High Mobility Concrete Batching Plant

HZS120 concrete batch plant is a type of concrete machine which adopts screw conveyor, its transmission system is divided into aggregate conveyor and powder conveyor.

1. Modular structure and convenient to install and remove

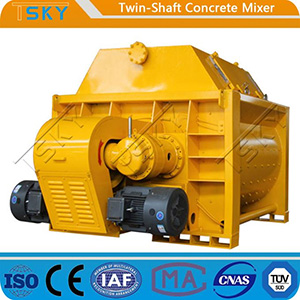

2. MS2000 concrete mixer and aggregate to enhance the use of twin shaft compulsory concrete mixer, high mixing quality and high efficiency.

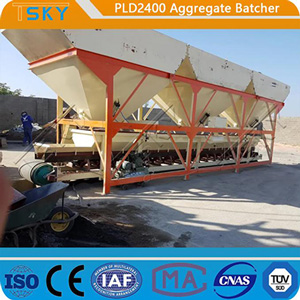

3. Aggregate batching using PLD3200 concrete batching machine, accurate measurement, high production efficiency.

4. Powder material is measured by electronic scale, and the proportioning accuracy is high.

5. Water using electronic scale measurement, will be more high accuracy.

6. Control System: The whole machine adopts computer control, which can not only control automatically, but also can be operated manually. The operation is simple and easy to control.

7. Suitable for small scale construction site, prefabricated parts factory and commodity concrete production plant, which is more suitable for railway, highway and other mobile strong concrete supply.

The Layout Drawings of HZS120 Container Moudlar High Mobility Concrete Batching Plant

|

Aggregate Batching System PLD4800 Customization 3/4 hoppers with belt conveyor, pneumatic discharging mode with independent/cumulative weighting. |

|

|

Twin-Shaft Mixer MS3000 Equipped with twin-horizontal shaft concrete mixer; Discharging height is 4.0m. Pneumatic/Hydraulic control, easy replacing of wearing parts, such as liner plates. |

|

|

Belt Type Aggregate Feeding |

Automatic control system Full-automatic PLC/Centralized control with the emergency stop button and safety control key. TV monitoring systems for batching machine, concrete mixer, and discharging mouth are optional for clients. |

|

|

Bolted Cement Silo modular making with dust collector, broken arch, pressure relief valve, level gauge |

|

||

|

|

Butterfly Valve |

||

|

Screw conveyor to feed powders |

|

||

|

|

Weighing system |

|

|